Everything you need to know about The Rodwell Compressor Company

The Rodwell Compressor Company (nee Rodwell Bayne) have been specifying, supplying and maintaining air compressors and associated equipment since the 1950s.

We pride ourselves to be knowledgeable, agile and efficient distributors of Air Compressors and Compressed Air Equipment covering Anglia, S.E. England and London.

We supply, install, service, repair and hire compressed air systems for a wide range of applications

Industrial Air Compressors

Screw Compressors, Vane Compressors, Piston Compressors, High Pressure Compressors & Oil-Free Compressors as well as compressor duty control.

Industrial Blowers and Vacuum Pumps

Medical, Dental and Laboratory Compressors

Air Treatment

Refrigerated Dryers, Super-Dry Desiccant Dryers, Filtration, Regulation

Pipework & Installation

Compressor House Installation & Factory Pipework of all types

Compressor Maintenance

At The Rodwell Compressor Company our engineers undertake Planned Maintenance, General Servicing, Emergency breakdowns, Equipment Overhaul and system remedial works.

We’re trained and have the full support of the manufacturers we represent including Gardner Denver (which includes Compair, Hydrovane, Champion), SCR Compressors, FPS Compressors and Beko Technologies.

Added Value Services

Written Schemes of Examination (WSE) for Pressure Systems Safety Regulations

Under the pressure systems regulations all users of compressed air must have a WSE.

The Rodwell Compressor Company are qualified and experienced to inspect your whole system and provide a Written Scheme of Examination so your organisation remains compliant and safe.

Our comprehensive WSEs are easy to understand and are supplied as a simple .pdf document to store electronically on your system and ours. We will even remind you when your next WSE is due.

Energy Audits & Advice

10% of all energy used in industry is spent generating compressed air.

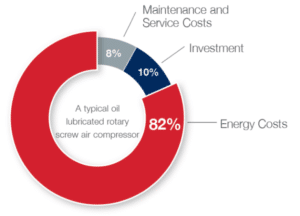

Over 10 years, the overall purchase price represents just 10% of the total cost of a compressor.

Other numbers….

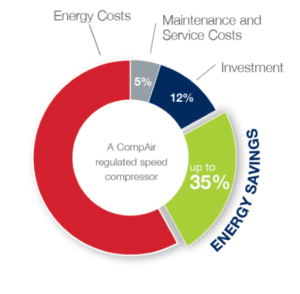

With a variable speed compressor, you’ll save more than the additional investment because of reduced purchase costs.

Typically a variable speed compressor will pay for itself completely within 3 years. And often within 1 to 2 years.

Invest in curing those leaks!

Would you take money out of your pocket and throw it on the floor? – Of Course Not!

But you’re doing exactly that if you’re ignoring those air leaks in your system…. A leak caused by a single 3mm hole will cost in excess of £300 per year.

So just a one-day investment in reducing leaks will pay for itself in well within 1 year and significantly improve your organisation’s green credentials simply, cheaply and effectively.

Visit The Carbon Trust’s website for more information about energy efficiency in compressed air systems.